ÃÏ√¿”∞‘∫ for Clinical LabsSolutions for a Greener Future

Siemens Healthineers is driving transparency and accountability in clinical laboratory sustainability.Ã˝

Clinical labs may‚ÄØoperate around the clock‚ÄØto test patient samples whenever results are needed. Traditionally, In Vitro Diagnostic testing requires significant amounts of water, energy, and plastic consumables, placing labs among the most environmentally taxing healthcare operations.Ã˝

As labs around the world grapple with their responsibility to care for the planet as well as their patient, it has become more important than ever to‚ÄØhave partners who support and enable sustainable solutions‚ÄØthat bring about greater efficiencies and less waste.Ã˝

The Atellica Solution portfolio ‚Äúeco-design‚Äù applies across the whole system design, manufacturing, and distribution framework, aimed to reduce carbon footprint and waste.Ã˝

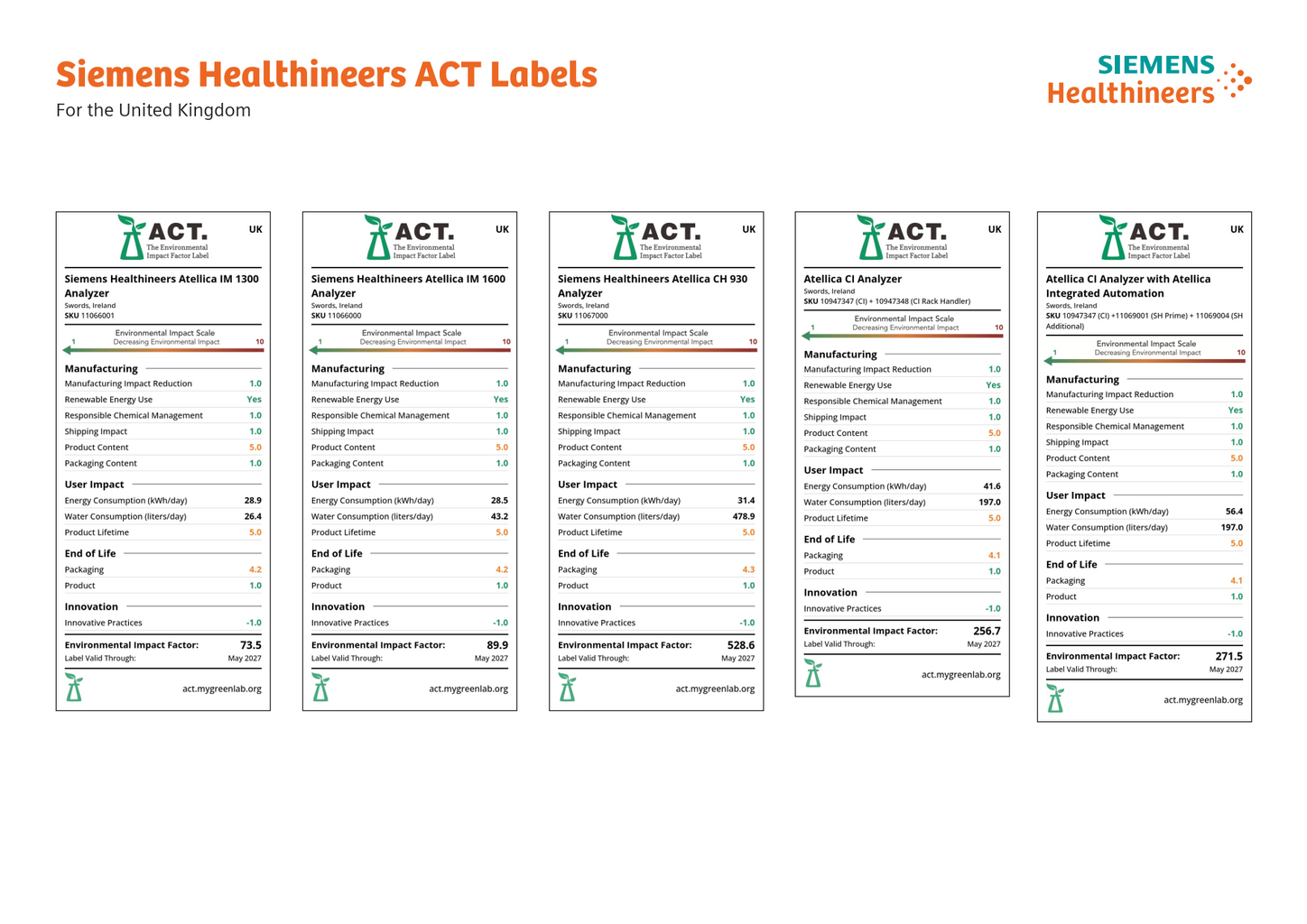

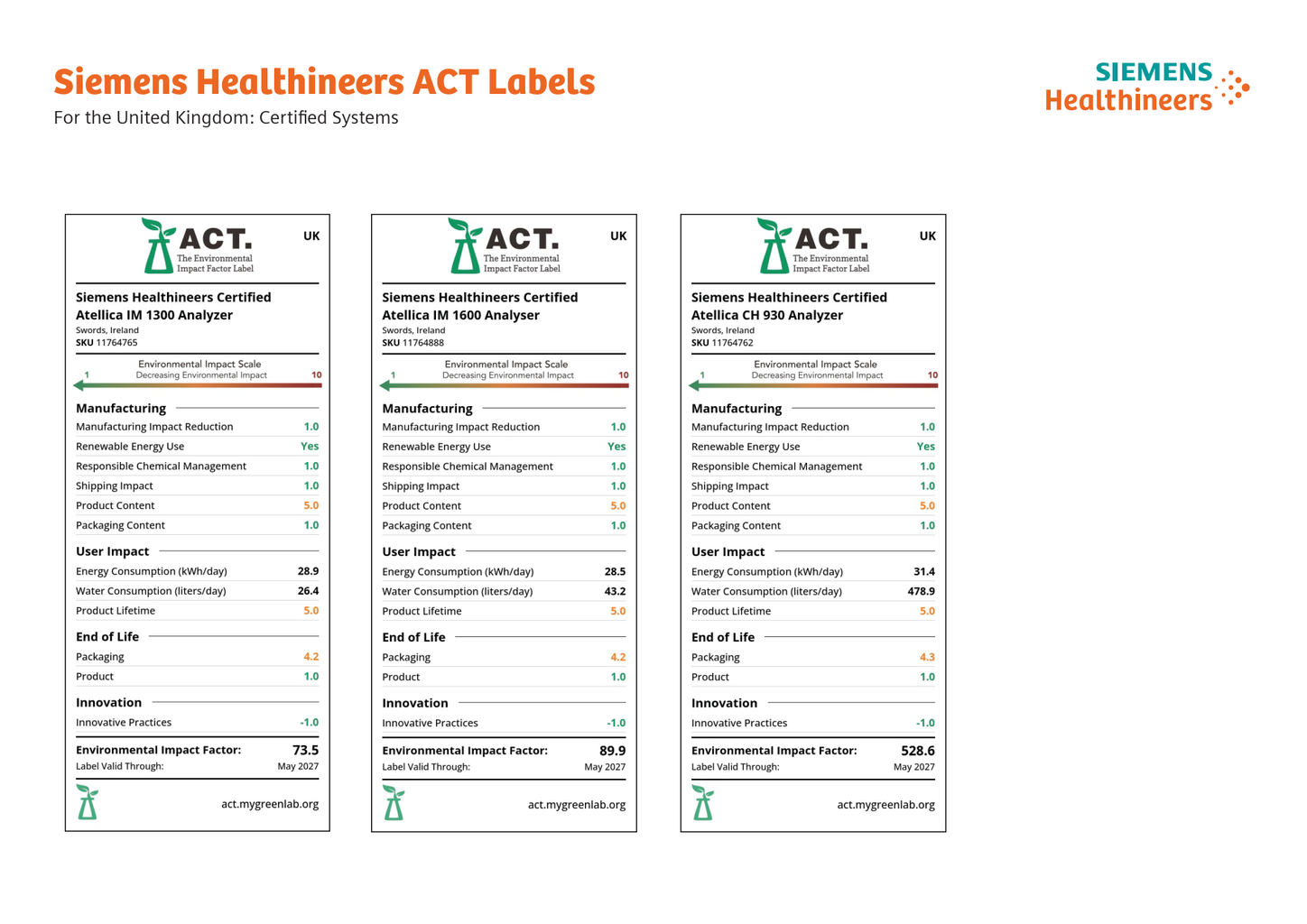

The Atellica Solution portfolio is the first clinical laboratory product line to achieve My Green Lab ACT Ecolabel Certification‚Äîc¥«±π±∞˘æ±≤‘≤µ analyzers and the reagents used with them.Ã˝